Mandau “malat”

| Object | Mandau “malat” |

| Culture | Borneo, East-Kalimantan, Dayak, Bahar-region, Kutai(?) |

| Time | 18th/19th century |

| Dimensions | Length 62 cm |

| Material | Steel, silver, non-ferrous metal, wood, rattan, deer horn, animal skin, animal hair, beads, hornbill beak attachment |

The object presented here is a mandau of exceptional quality. It can be ascribed to the ethnic group of the Kayan, who are resident in East Kalimantan (Indonesia, West Kutai regency) and can be classified as Bahau-Dayak after the settlement area. The term covers about 60.000 – 100.000 people, depending on their identity. The kayans (like the other Dayak) are heterogeneous and terminologically an ethnogenetic-political construct; the kayan languages alone, for example, comprise 17 subgroups.

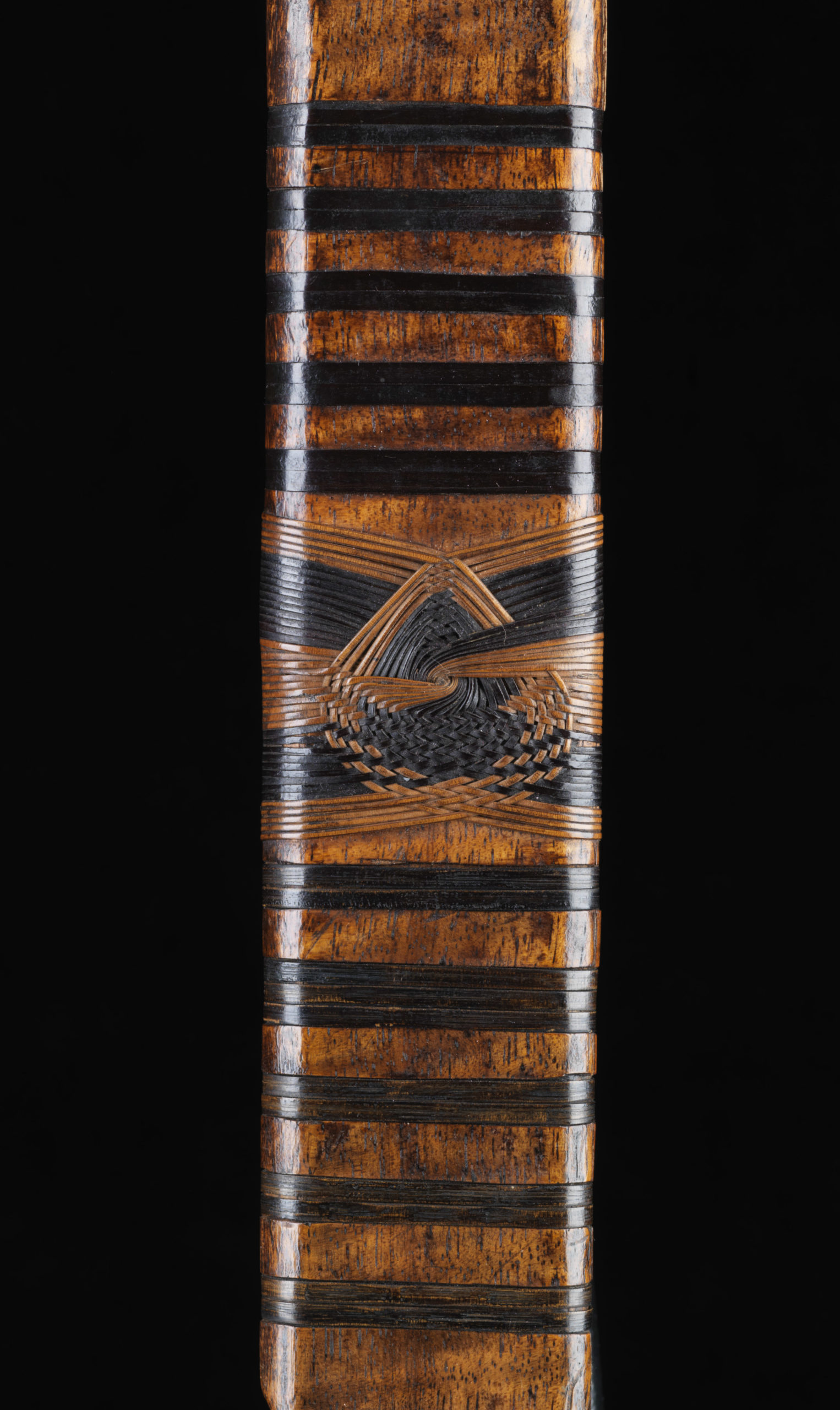

The blade is a very fine work of refined steel with silver and brass inlays. The scabbard is wrapped in two-tone rattan bands and decorated with elaborately carved wooden decorations with aso motifs, which are attached to a piece of animal skin. Animal hairs, partly dyed red, are arranged on the animal skin on the back side under the blackhead. The blackhead, which is worked in two colours in wood and staghorn, partly in striped pattern, could still be original. The carrying strap of the mandau is braided from rattan and has a button at the end made from the hornbill’s horn and a red coloured string which is decorated with numerous beads at the end. Spirals and aso motifs, as well as remains of multicoloured animal hair decorate the handle made of deer horn, which is inserted into a wooden peg wrapped in dammar resin with a fine silver wrap.

The mandau shows a clear refined structure and is probably made of locally melted iron or steel. Although technically inferior to the industrial qualities, it enjoys a particularly high status. In Nieuwenhuis’ time it was already unusual to melt iron oneself; only the Longglat were apparently still active in the “smelting business” around 1900. Smelting took place in shallow earth pits, which were alternately filled with charcoal and ore and then melted down under air supply (double piston blower). Steel production has a long tradition on Borneo. In Santubong (Iban: Si-antu ubong; “ship of the dead person’s soal”) and in the Niah Caves near Brunei, many indications of extensive iron smelting (slag) since the T’ang period have been found. Corresponding finds have also been made in Bukit Maras, Bongkissam (Sarawak Delta) in Tanjong Kubor Bay and on the Buah River. From Apo-Kayan comes the once famous Mantikai iron (traditionally the best iron for mandau). The Tayan / Kapuas areas have been known since ancient times among the Dayak for iron deposits and good material.

Supplementing Literature Back to room view